Attic Ladders — Australian Made by AM-BOSS

Premium Quality

Free shipping over $200*

Fast Delivery Australia-wide

Product Description

Are you looking for sturdy, safe and reliable access solutions for your home or workplace? Defer to AM-BOSS, the industry professionals, for assistance. We have designed, manufactured, installed and distributed purpose-built pull-down access ladders (attic ladders), fixed access ladder systems and more — nation-wide — since 1979. We expanded our range to include the supply and install of Fall Arrest Systems to compliment our access systems to offer a complete, safe access system that complies.

Not only are our pull-down access ladders (attic ladders) popular in the international market but they also comply with the Building Code of Australia (BCA) and are CodeMark certified for quality assurance.

Attic ladders made by AM-BOSS are so versatile that we can customise our designs to suit just about any situation.

Domestic

Optimize your ceiling storage space and make the most of your available space.

Commercial

Improved access to ceiling voids, mezzanines, plant rooms, rooftops and more via climbable systems that are purpose-built for specific sites.

Fire-Rated

AM-BOSS ‘Inferno-Boss’ is 100% Australian owned and made, and Fire-rated to AS1530.4 with a -/90/90 rating and Load Rating of 200+kg.

Concertina Stairs

Electric operated and automated for your convenience.

Prices

CONTACT 0882960044 OR 0882960955

AM-BOSS Access Ladders are CodeMark Certified

! IMPORTANT ! READ ALL OF THIS TEXT, TO PREVENT INJURY AND AVOID MISTAKES

GUIDE TO INSTALLATION FOR TYPES: ‘ACCESS-BOSS™’

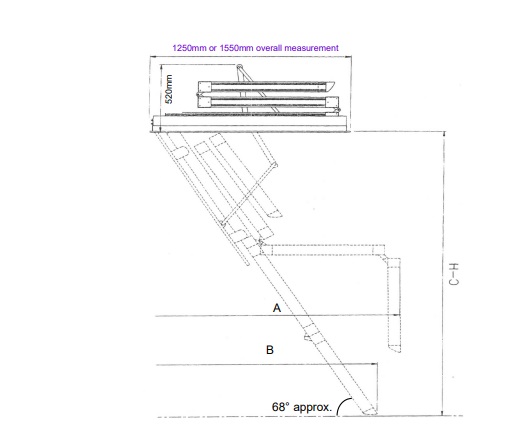

STEP ONE: To get started, find the right location. Easy access top and bottom is essential. Make sure there is enough room to unfold the ladder (refer to Diagram / Table overleaf – Maximum Clearance at 60°).

IMPORTANT NOTE: CUT-OUT NOT TO BE WIDER AS SHOWN (570mm)

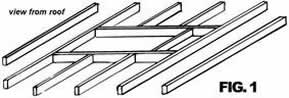

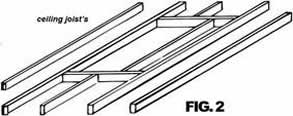

STEP TWO: What you need to make the opening – Timber Joist (Fig. 1 and Fig. 2): Timber, MPG10, 90x45mm pine or hardwood, about four (4) metres will be enough, pick a straight piece with minimal knots, and about 2 doz. 90mm long nails.

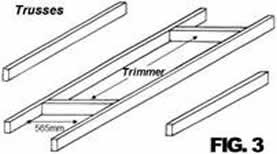

What you need to make the opening – Trusses (Fig. 3):

Trusses at 600mm centres should give you a clear distance of 565mm between. Insert a trimmer at length of 568mm (if Trusses are spaced at less than 565mm in between, smaller hatches can be manufactured at extra cost). DO NOT CUT TRUSSES without Building Surveyor approval.

Web of trusses NOT SHOWN for clarity of sketch.

To mark out the opening on the ceiling: Either (from below) hammer nails through the plaster or (from above) measure from the top plates of the walls, which are usually visible. DO NOT STAND on the plaster ceiling or on timber joists that you had to cut, before it is nailed back to secure timber. A short plank is handy. It is best to do the timber work first, from above. Double check the cut out size and measure diagonally for square, if correct, cut out the plaster. You are now ready to install the unit.

Once the opening in the ceiling has been made, installation is a breeze.

! IMPORTANT ! READ ALL OF THIS TEXT, TO PREVENT INJURY AND AVOID MISTAKES

STEP THREE: Installation of the pull-down access ladder, into the readymade opening: Fit eyebolt to panel. Make sure opening end of hatch is where it should open and have someone assist you for 5 minutes to push the fully assembled access ladder into the ceiling, ensuring the architrave is hard against the plaster. The unit is now in the right position and should not fall back out – fitted Fixing Clips will take care of that. Gently open the hatch panel with the hook & pole supplied, by placing the hook through the eyebolt, (at this time, with one hand keeping pressure against the architrave at the opening end) immediately screw one screw (8 x Type 17 Hex screws 12-11 x 65mm supplied, or use similar) into each pre-drilled hole on either side at opening end through frame to timber to secure. Unfold the ladder. DO NOT WALK ON THE LADDER AT THIS TIME. Now screw remaining six (2×3) screws into the remaining pre-drilled holes. You may have to loosen or tighten the eight (8) fixing screws on one side or the other to adjust the gap evenly on both sides between the architrave and the panel. Now all you have to do is adjust the ladder (two screws with lock nuts – refer Adjustment sticker inside frame), so that feet are on the floor and hinges are closed ie butted against each other, finished.

If you cannot get someone to help you: Remove the ladder assembly only from the panel, (4 or 6 nuts depending on model) to lighten the load. Make sure the hatch panel opens at the right end. With a rope, pull the hatch from above into the ceiling. Make sure the hatch-architrave is hard against the ceiling. Fix the frame by screwing the eight screws (supplied) through frame to timber to secure. From below open the hatch, ! ATTENTION ! Be careful – without the weight of the ladder it is possible for the panel to fly up. Keep the ladder assembly nearby and fit it back on the panel with the 4 or 6 nuts. Do not over tighten the nuts. You may have to loosen or tighten the eight (8) fixing screws on one side or the other to adjust the gap evenly on both sides between the architrave and the panel. Now all you have to do is adjust the ladder (two screws with lock nuts – refer Adjustment sticker inside frame), so that feet are on the floor and hinges are closed ie butted against each other, finished.

You are now ready to enjoy your new access system.

! IMPORTANT ! READ ALL OF THIS TEXT, TO PREVENT INJURY AND AVOID MISTAKES

OPERATING AND MAINTANANCE PROCEDURE

ON AM-BOSS ACCESS LADDERS

Am-boss Access Ladders work on a reliable counter balance spring system.

OPENING

Engage hook on pole (supplied) into small eyelet on opening end of ceiling access panel. Gently pull door open till it comes to rest against the stops on the adjusting mechanism. No need to unhook the pole from the panel. With both hands unfold and extend the ladder to the floor.

CLOSING

With both hands lift up bottom section of ladder and fold back up on top of each other. With the use of the pole gently first push then ease panel back up till it is fully closed. The spring counter balance system will keep the panel shut.

MAINTENANCE

All moving parts are factory pre-lubricated and lubrication should not be required for some time. However should operation of the unit be in excess of 3 to 5 times a day, all moving parts are to be lubricated once every two months. Most important is the lubrication of the Pivot Point of the linkage-arms joined to the side plate with the adjusting system. This part does most of the work.

INSPECTION OF THE WHOLE SYSTEM SHALL BE CARRIED OUT ONE A YEAR AND ACTION TAKEN

Cut out NOT TO BE WIDER as shown (570mm)

Ceiling cut-out sizes: Model No’s 2153 to 2680 – 1220mm x 570mm

Ceiling cut-out sizes: Model No’s 2830 to 3840* – 1520mm x 570mm

* Ceiling cut-out for Model 3840 for ceiling heights from 3945mm to 3995mm – 1620mm x 570mm

| MODEL | CEILING HEIGHT | UNFOLD (A) | REST POINT (B) |

|---|---|---|---|

| 2153 | 2150mm-2300mm | 1595mm | 1465mm |

| 2345 | 2300mm-2450mm | 1670mm | 1525mm |

| 2460 | 2450mm-2600mm | 1720mm | 1555mm |

| 2680 | 2600mm-2800mm | 1830mm | 1700mm |

| 2830 | 2800mm-3000mm | 1950mm | 1790mm |

| 3020 | 3000mm-3200mm | 2050mm | 1855mm |

| 3240 | 3200mm-3400mm | 2145mm | 1970mm |

| 3460 | 3400mm-3600mm | 2210mm | 2005mm |

| 3680 | 3600mm-3800mm | Manufactured on-grade at 68° approx., to exact ceiling height |

|

| 3840 | 3800mm-3995mm | ||

| From 4000mm Measurements and Cut-out To Be Advised | |||

NO ASSEMBLY, NO CUTTING, NO MISTAKES.

Refund Policy

All goods to be returned to 678 Brighton Road, Seacliff Park, SA, 5109

Returns are accepted within 30 days of delivery. Any items returned must be in the original packaging and must be in an unused, as new condition. Any return shipping charges are the responsibility of the customer. Custom made products and drawer organisers that have been correctly cut to the size provided to us by you can not be returned, unless they are faulty or have been made incorrectly.

Before we pack and send an order, our products are thoroughly inspected and carefully packaged. We use as much recycled material as possible for our packaging. If items are damaged in transit, please inform us within 7 days of receipt of goods. Please email a photo of the damaged goods with a reference to your receipt number.

A refund or exchange can be requested if the product you have purchased is faulty, has been damaged during transit, has been misrepresented in some way or doesn’t do what it’s supposed to do.

Goods purchased from our website may only be returned after authorization from The Storage Shop, by contacting us via email at info@thestorageonlineshop.com.au or by phone on (08) 8296 0955. After inspection of returned goods a refund or exchange will be arranged.

Shipping fees that the customer incurs, in returning the product back to The Storage Shop are non-refundable, freight cost incurred in sending the goods to the customer is non-refundable, EXCEPT in the case of a product that has been damaged during transit to the customer or if a product is faulty.

Return Policy for Free Shipped Product (In case of Change of Mind)

In case of a ‘FREE Shipped Product’ return, you are required to freight the goods back to The Storage Shop, at your own expense, plus you will incur a $35 administration fee, that will be deducted from the amount refunded to you. Contact us via email at info@thestorageonlineshop.com.au or by phone on (08) 8296 0955.

Shipping Policy

WE DELIVER AUSTRALIA WIDE

Free shipping over $200 to most of the states(South Australia, New South Wales, Victoria, Australian Capital Territory and some part of Queensland are including in free shipping over 200 dollars orders). Some part of Queensland, the whole Northen Territory, the whole Western Australia and Tasmania are not including in the free shipping over 200. Please call 0882960044 for further details